back to part I

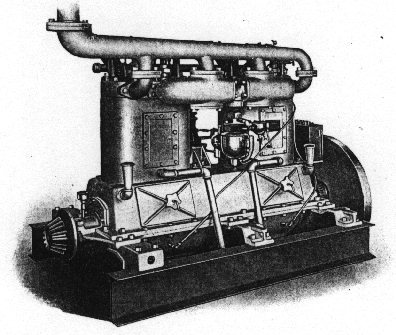

Step 4: The Engine-

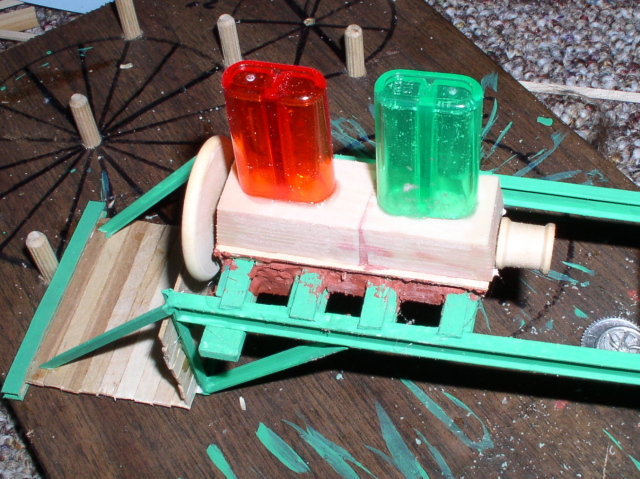

Once again, I cheated on building the oil pan. Since it is a static

model, and there is no crankshaft or any need for the pan to hold oil,

I made the pan in sections rather than cut reliefs in the crossmembers.

Spot putty and paint will make it hard to tell.

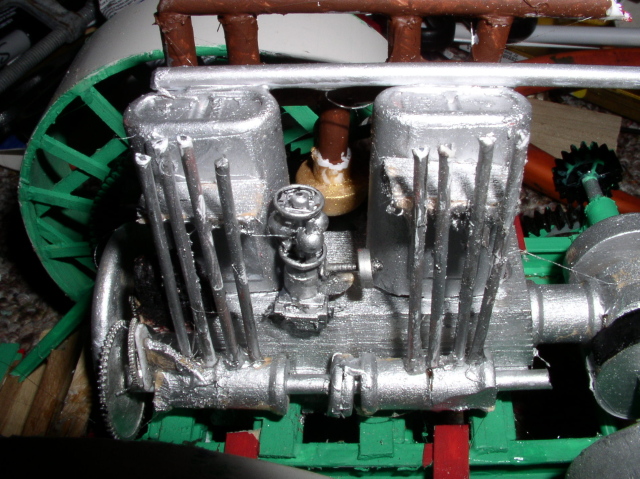

The block is a couple of 'crates' from the Lionel pieces mentioned on

the previous page cut and spliced together to 2-1/2" long. This is a

real good use of useless parts...they have too much taper to be of use

for anything else but hog troughs. The cylinders are the bottoms of a

pair of Scripto lighters, make these 1-1/4" tall. The flywheel a 1-1/2"

wood disc, the block extension is a 1/2" spool, both from the craft

shop.

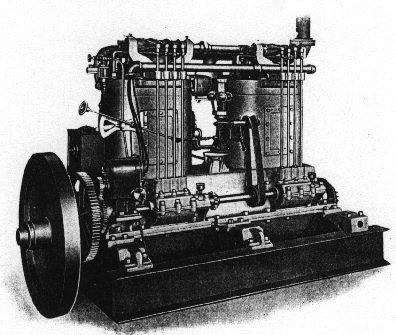

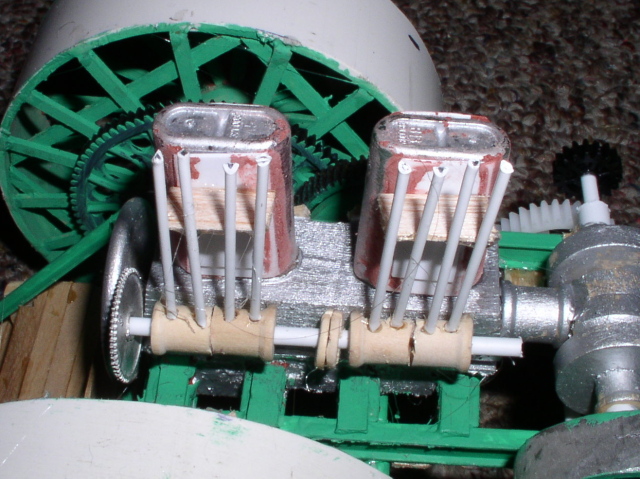

The camshaft was made from styrene plastic tube, four 3/8" wood spools,

and a whitemetal gear casting from Ozark Miniatures. I found that it

was mounted a bit too high here, and will need to be lowered to clear

the steering gear. The lighter tanks were plated wth styrene to give

them a bit more thickness. An alternate cylinder design would be pieces

of 3/8" wood dowel, or styrene tube bridged together with thin styrene

to form a 3/8" x 1" oval shape.

The governor is a bit of broken c-16 rod, 3 plastic seed pearls, 2 #3

snaps, a picture nail, wire, and a small wheel from Ozark. It will be

mostly hidden on the finished model, so I didn't spend a whole lot of

time on it....

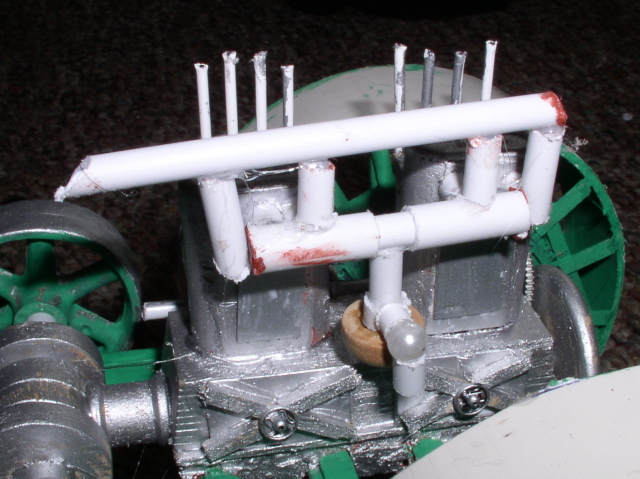

Repositioned camshaft, installed governor, and Dixie magneto made from

bits of coffee stirrer then cardstock, styrene, and a couple Ozark

gears.

The manifold is just various sizes of styrene tube, the carb is tube, a

wooden axle cap, and a small plastic pearl. I left the vertical exhaust

pipe off for now because it would just be in the way.

Alternate later carburetor style, courtesy of Mr Kelly Tytlandsvik

Step4A:The rocker arms and valves-

The rocker arms are more of the spoke material, the valve 'springs' 2-56 nylon screw stock.

Step5: the drivetrain-

On to page 3

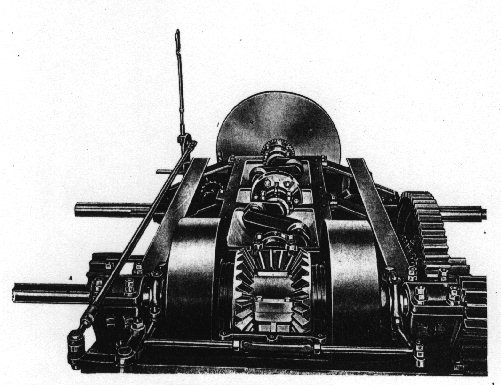

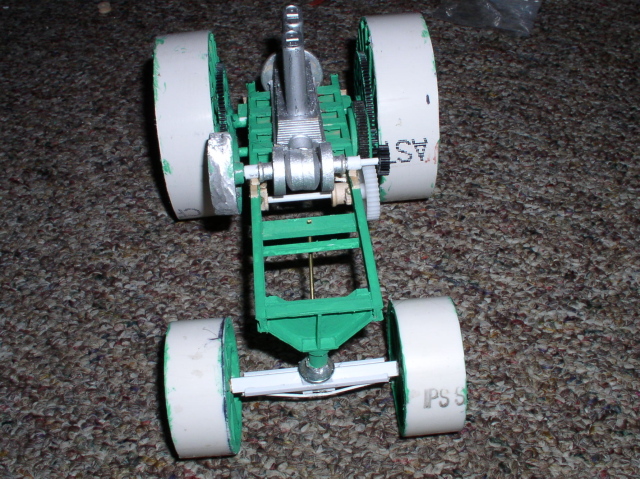

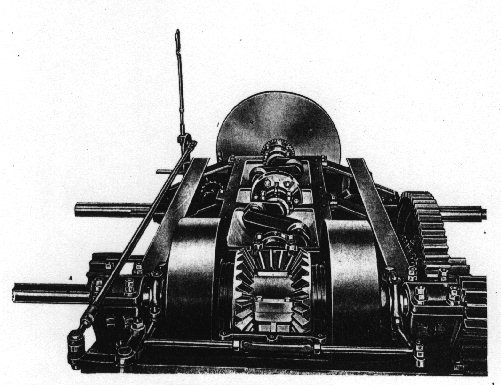

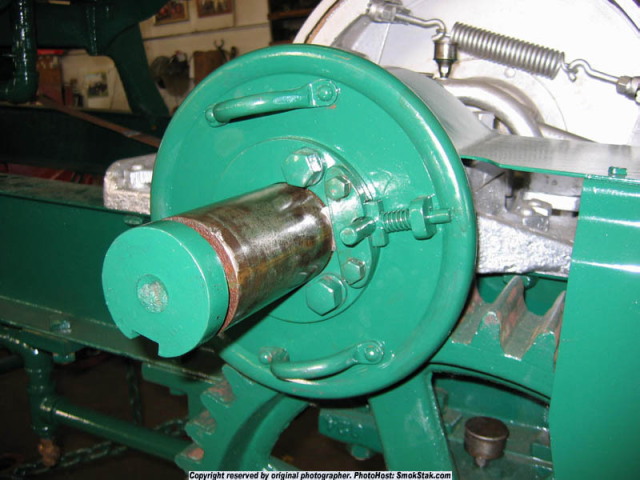

The pinions are E-flite EFLH1455 pressed off the shaft, the white intermediate

gear is a Parkzone PKZ1504, the differential gear I had in a box and two 1-1/2" wood

discs... Unfortunately, this gear doesn't mesh with the

others, which isn't critical in a static model, but is visually

noticable, and will be replaced when I locate a 2" gear with the proper

pitch. (Note: Always pay attention, somebody mounted the differential

on the wrong side in this pic... left and right are reversed when you

turn something upside down. Just 10 seconds to fix it, but a good

visual reminder!

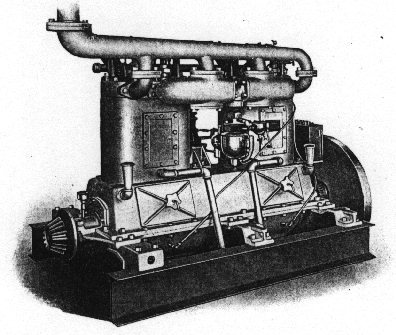

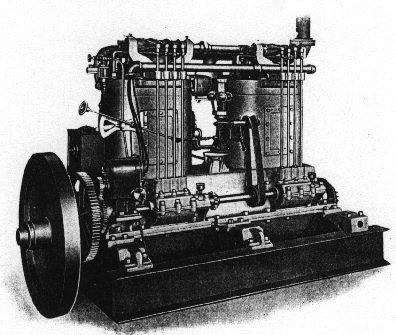

The Flour City tractors used two bevel gears and clutches on a single

shaft to provide forward and reverse. These were linked together so

that only a single johnson bar was needed.

The model's primary drive consists of two 7/8" wooden plugs glued back

to back for the bevel gear case, two 1" x 1/4" wood wheels for

the clutches, and a 3/8" spool cut in half for the throwout bearings.

The linkages will be added in a later step.

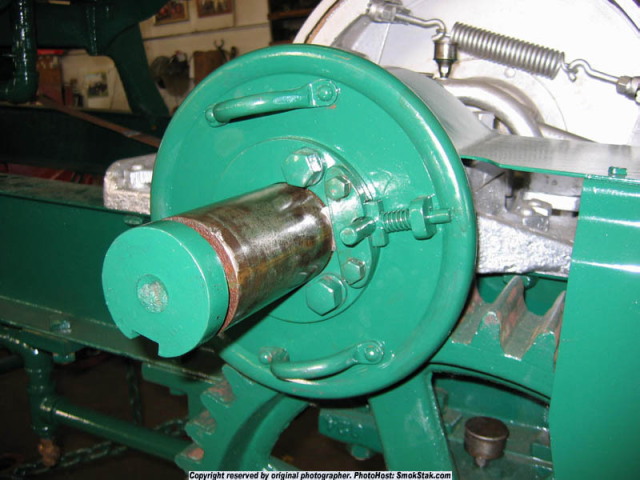

To disengage the gear train for stationary belt work, the primary

pinion is shifted out of line by hand the spring loaded dog holds it in

the desired position. (photo courtesy of Mr. Tytlandsvik)

On to page 3